Corrpro Corrflex

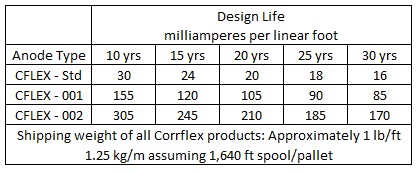

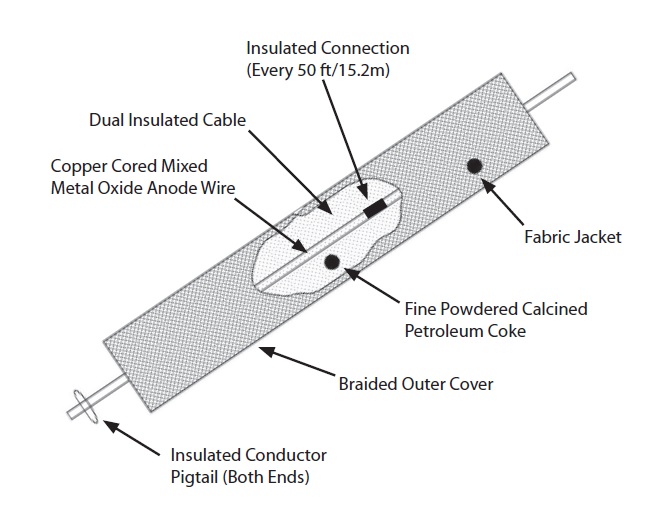

Corrpro’s Corrflex anode system brings together the lightweight and high-performance characteristics of copper-cored, mixed metal oxide (MMO) anodes with the rugged, field-tested worthiness of a fabric jacket filled with powdered, calcined petroleum coke. Corrflex is factory assembled to the highest quality standards that only Corrpro Certified products can claim.

Corrpro offers a full line of Corrflex anode systems that can be customer designed to suit virtually any linear application. Corrflex utilizes copper-cored, mixed metal oxide, and titanium-based anodes that enhances the linear conductivity of the anode element. Because the mixed metal oxide is surrounded by high carbon content powdered backfill, the Corrflex anode system can be installed without the need for additional coke breeze. Connections to the continuous insulated conductor are made redundantly every 50ft, further ensuring a minimum voltage drop own the entire anode length. Corrflex systems come standard with 40 ft (12.2m) of insulated conductor “pigtails” at each end, to allow for bidirectional power feeds.

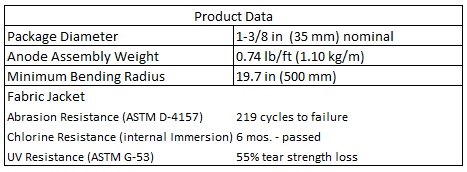

The proprietary Corrflex manufacturing process assures that the anode assembly is centered in the carbon backfill. The outer jacket of the Corrflex package is a chlorine/low pH resistant porous fabric that is covered with a protective cross braid for superior abrasion and damage resistance.

Corrflex comes standard in 1,640 -foot (500m) lengths. Custom lengths can also be made to order. The continuous standard cable is #8 AGW, seven strand copper cable with chlorine resistant HALAR insulation. The Overall nominal Diameter of the Corrflex packaged system is 1-3/8 inches (35mm).

• Packaged with #8 AWG or #6 AWG HALAR cable and petroleum coke breeze powder

• Standard roll size of 1640 Ft (500m)

• Custom lengths available upon request

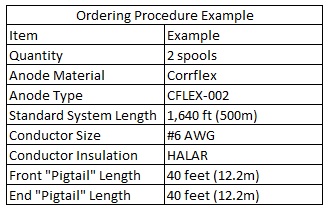

Corrflex anode systems are available in various standard output designs or can be customized to your requirements. To order, indicate the Corrflex model you desire, length per spool, and number of spools required. An example is provided below to illustrate the process.

800.826.7891

11616 W 59th Street

Sand Springs, OK 74063

Ph: 918.245.8791

Fax: 918.245.8798

Corrpro Canada Materials & Corrpower Manufacturing

10848 – 214 Street N.W.

Edmonton, Alberta T5S 2A7

Phone: 780.447.4565

Materials Inquiries: cpcaquotes@aegion.com